How to Manufacture A Tire

The followed steps are the main processes for manufacturing a tire, which can help you to have a overview about tire production.

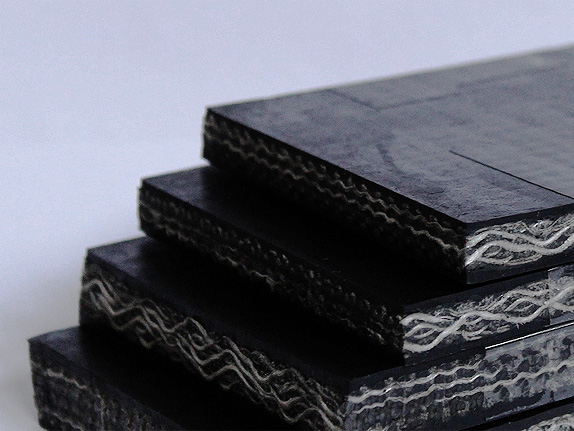

Compounding and mixing

Compounding is to bring together all the ingredients required to mix a batch of rubber compound. Each component has a different mix of ingredients according to the properties required for that component. This is the first step to manufacture a tire.

Components consists of three classes based on manufacturing process: calendaring, extrusion, and bead building. This is the stage to prepare fully to manufacture a tire.

Tire building

Tire building is to assemble all the components onto a tire building drum. Tire-building machines can be manually operated or fully automatic. Its operations include the first-stage operation, where inner liner, body plies, and sidewalls are wrapped around the drum, the beads are placed, and the assembly turned up over the bead. In the second stage operation the belt package and tread are applied and the green tire is inflated and shaped.

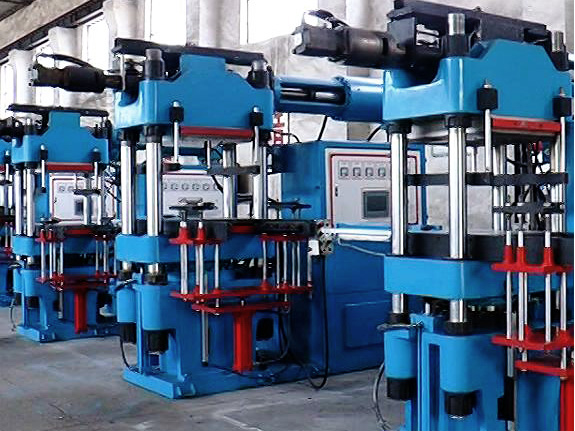

Curing

Curing is the process of applying pressure to the green tire in a mold to give it its final shape, and applying heat energy to stimulate the chemical reaction between the rubber and other materials. During this process the green tire is automatically transferred onto the lower mold bead seat, a rubber bladder is inserted into the green tire, and the mold closes while the bladder inflates.

The tire uniformity measurement is a test where the tire is automatically mounted on wheel halves, inflated, run against a simulated road surface, and measured for force variation. Tire balance measurement is a test where the tire is automatically placed on wheel halves, rotated at a high speed and measured for imbalance. In the final step, tires are inspected by human eyes for numerous visual defects such as incomplete mold fill, exposed cords, blisters and others.

Tire testing

When designing tires of new specification, it is necessary to carry out numerous tire testings to ensure the tire can meet the requirements.